Wednesday 2 May 2018: Visiting the Morgan factory

We begin our day with a hearty breakfast: Gabi eats porridge while I have an English Breakfast. Now we’re ready to visit the Morgan factory!

The Morgan Motor Company produces small sports car by hand since 1909. It’s the oldest car manufacturer that is still owned by the founder’s family, and the last car manufacturer to use frames made out of wood. AND the only one that allows photos during the factory tour! Jay!

The entrance to the factory and the way to the visitor parking proves that it’s not just a faceless mass production. The brick buildings host a part of the manfuacturing process each and I assume they were built one after the other as the range of cars produced expanded.

Two of the three iconic models may be found on the visitor car park: The 3 Wheeler with which Morgan startet, and (in the back) the 4/4 which has four wheels and four cylinders and which is available in different models (also with six and eight cylinders).

The factory tour begins with a film that also includes the halls that we cannot visit, for example the paint shop or the development office with secret new designs. A few different models are on display in the first hall. The car in the front is an Aero 8, an eight cylinder sports car known for its cross-eyed headlights.

From here we continue from hall to hall. Body parts are mounted on the steel or aluminium chassis, which are manufactured by hand on site. Most consist of an ash wood core, over which a piece of sheet metal is fastened. Take the mudguards for example. Three wooden boards are glued together and then bent into the right shape in a frame. The frame is 60 years old and there is no replacement for it. This results in a wooden construction that is very resistant, but nevertheless quite elastic and bends back again if it is bent. And it’s light.

The dashboards are made from wood by hand too, always by the same guy, Dave.

The tour is unbelievably interesting and you can see with what joy the many employees are working. Many have been here for a long time, and there are still many apprentices who are interested in making cars by hand.

Outside the halls there is always something going on. Finished vehicles are tested, body parts are carried around, or an engine (only on a chassis) is started for the first time.

These are the finished vehicles waiting to be delivered to the customers. Every car is produced on order only. The waiting period is approximately one year.

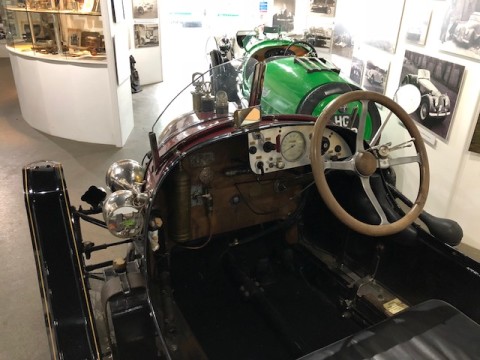

In the small museum you can see a lot from the beginnings of the brand. Besides the office of founder H.F.S. Morgan, one of the first tricycles he produced is also located here. He had built one for himself, as an in-between between motorcycle and car, and then received so many requests from friends and neighbours that he decided to start production.

We’re rather hungry and exhausted after two and a half hours of visiting the factory and the museum. We have a sausage roll and a quiche at the factory’s café before driving back to the hotel.

After a nap, our energy levels start to raise again. And we’re getting hungry. We stay at the hotel’s restaurant where we have a Caesar salad (Gabi), a sirloin steak (me) and we share a warm brownie with vanilla ice cream.